This post is long overdue, but it’s the first chance I’ve had to sit down and write it. I’m typing this from the nav station on Isbjorn. We’re anchored in Grand Case, a pretty little bay on the French side of St. Martin. The wind is gusting down over the hills to the east, hitting the mid 30’s in the big puffs and whirling us around on the anchor. It’s Easter Sunday. Note: Scroll down to the bottom for detailed photos with captions on the whole repair.

We sailed up from Antigua overnight on Thursday, leaving around 10pm to avoid the superstition of not leaving on a Friday. An uneventful passage save for the fact that it was Liz’s first time offshore, so a momentous occasion for that (Liz is our new 59 North intern, a marine bio student at UConn who is helping produce the podcast, among many other things she’ll learn about running a small business. As a perk, she gets to come sailing with us!). She didn’t get seasick and learned to steer by the compass within the first five minutes of taking the helm. Impressive.

The passage was the first chance we had to test out the rudder repairs. You know the end of the story already - we got here, and all is well, the boat’s steering system more robust now than it’s ever been, even when she was new. But I’ll give you the long version too.

So What, Exactly, Happened?

The last thing I wrote came after the Caribbean 600 race, which you might recall, we had to abandon about ⅔ of the way around the course when we first discovered the problem. During a routine check of the rudder in the lee of Guadaloupe, I’d discovered what I’d long feared - the fiberglass joint wrapping the bearing that supported the rudder post where it goes through the hull, had failed. Water was seeping through and the entire bearing race was moving slightly, now un-bonded from the glass. Worse, when the helm loaded up, the entire rudder post rocked about half an inch from side to side. It was an easy decision for Paul and I at the time to abandon the race and ease the boat back to Antigua.

What I hope was clear in that last post was that this failure wasn’t because of the race at all. Rather in reality, the steering system had been compromised all along, probably for years, just nobody ever inspected it closely enough. I’ve never said this before, but the rudder was something that had been on my mind for a while now, given the ambitious offshore schedule we have with the boat. It was the only real critical system on the boat that we didn’t address at the fall refit. Almost exactly a year ago when we first delivered Isbjorn south from Connecticut, my friend Tom Herrington and I discussed whether we thought that fiberglass joint was leaking water, or if it was just the packing dripping down over it (which was definitely leaking). I chose to think it was just the packing. Turns out our initial fears were indeed true. To Tom’s credit, at the fall refit, he practically insisted I get someone to look more closely at it, and I didn’t. I even later wrote about it to Mia in a panicked email earlier in January when the furling unit first failed, when I was at my lowest point emotionally since we bought the boat and started the business:

…”I don’t trust the rudder bearing…” I’d said to her then (among many other, much much more embarrassing things!). It was prescient.

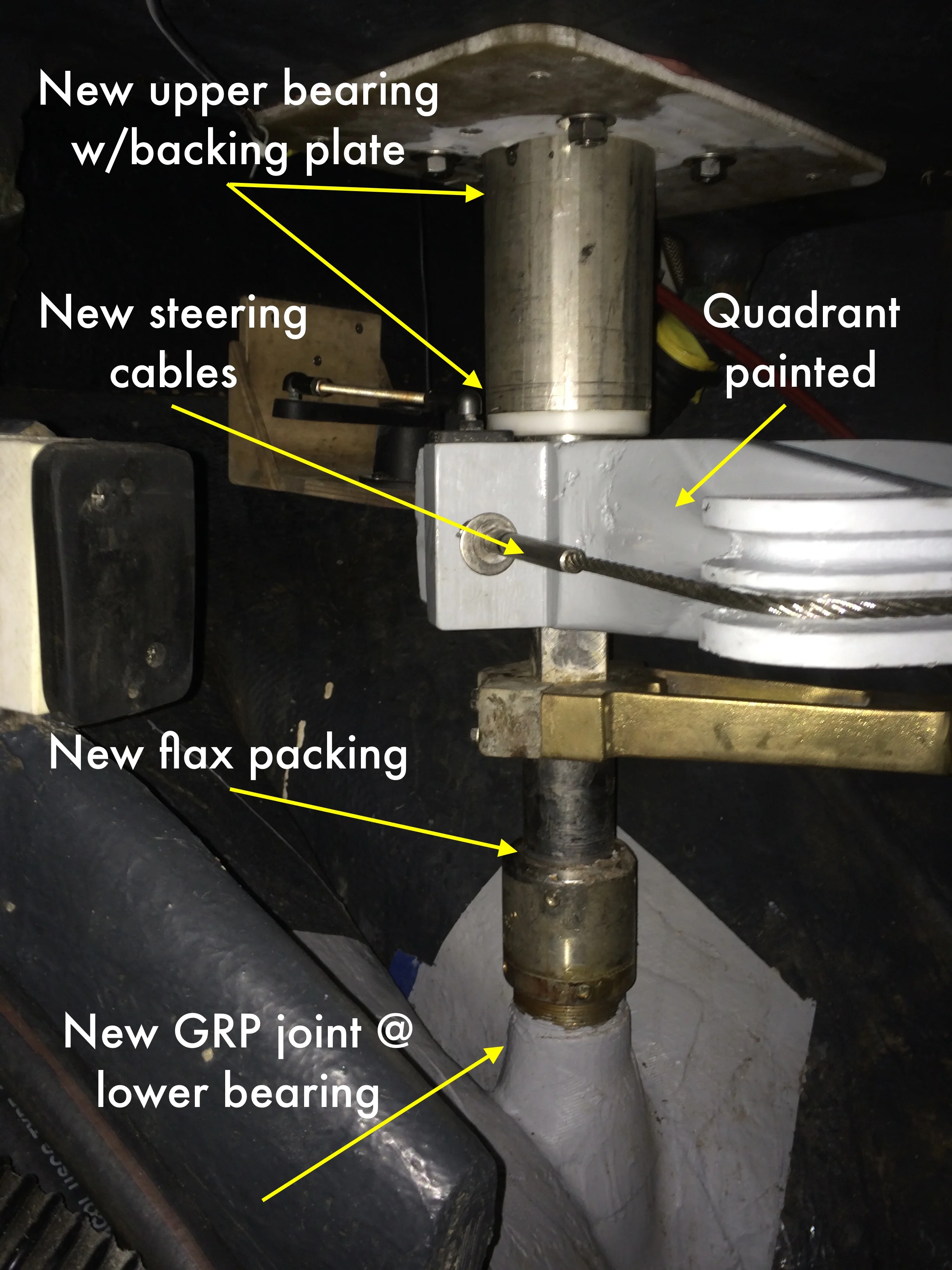

Once we got Isbjorn hauled out at Antigua Slipway and started investigating further, we realized the cause of the entire problem - the rudder stock was not properly supported at the top. From the lower bearing to the top of the stock was about 24” or so, the quadrant attached about halfway up. Without the top supported, everything the helm loaded up, a lot of sideways torque was put on the rudder stock, slowly working the joint loose over the years on the lower bearing. Re-glassing that lower bearing wouldn’t solve the ultimate problem - that would have to be addressed by building an entirely new upper bearing that would secure the top of the rudder stock to the underside of the cockpit sole, thereby eliminating that sideways torque.

How We Fixed It…

Oliver of Antigua Boats set to work almost immediately (thanks to Jonty, a fellow S&S Swan 48 owner for the referral!). On a Monday afternoon the boat was hauled, and by Tuesday morning the rudder was already out of the boat. It’s a skag-mounted rudder, attached to the skeg by a huge, solid bronze shoe bolted on by five or six 10mm bolts. Oliver and his mate James cleverly welded big nuts onto the heads of the bolts in order to get a big socket wrench on them for removal. The shoe itself was bonded to the fiberglass skeg with loads of epoxy, so it took a lot of persuasion from a heavy hammer and a butane torch to get it undone. Thankfully, Mia and I had by then retreated to ur shoreside apartment to let the guys get on with the dirty work.

The work proceeded in a couple of parts - re-glassing the lower bearing, sealing the bottom of the bearing race to prevent water intrusion, and designing and fabricating the upper bearing that would bolt onto the underside of the cockpit sole. ‘While they were at it,’ I had Oliver and his crew replace the teak on the cockpit seats and fair in some parts of the keel that had been damaged by a light grounding (some of the old fairing had broken off in small bits - purely cosmetic). They also sealed the garboard drain in the keel.

In the interim, Mia and I flew home to the US to run the World Cruising Club’s annual Ocean Sailing Seminar. On the Saturday of the seminar, after all the work on the rudder had been completed (we were to launch the following Tuesday), we had a scare as I read a news headline about a 6.0 magnitude earthquake centered only 90 miles from Antigua! I called the marina immediately, but they assured me the boat was still standing.

We returned to the boat to find a very nicely repaired steering system. The lower bearing was heavily glassed into the hull and the packing was replaced inside the packing nut. Oliver even fabricated a new packing wrench for us so I could further tighten the packing nut once we sailed for a bit. The upper bearing was a very solid affair, heavy-walled stainless pipe with a wide flange on top and a delrin bearing pressed into the bottom. The whole thing slid in from the top of the cockpit sole and was through-bolted with a 12x12 heavy-duty backing plate behind it, and supported the top of the rudder stock. The steering quadrant was polished and painted, the cables replaced, new bolts put into the bronze rudder shoe.

Weirdly, since dealing with this rudder issue on our boat, I heard from several other ‘old boat’ owners of exactly the same problem. The classic woods sloop The Blue Peter who we’d dueled with on the starting line of the 600 had to enact the same repair, as did another British ketch built in the 70s that we met on the dock at Slipway. If I were to buy an older boat again, I’d specifically ask the surveyor to take a very close look at the steering system to see if there were signs of this kind of problem. The total cost of the repairs - including the boatyard haul, launch & storage bill, bottom paint, the teak in the cockpit and fairing the keel - came to just over $17,000.

The First Post-Repair Sea Trial

Given our tight schedule, we didn’t have much time to sea-trial the repairs. We returned to Antigua last Tuesday, launched on Wednesday and set sail for St. Martin on Thursday. We still have 150 miles to go to get to Fajardo where our next trip starts, then over 1,000 miles to Key West, so it’ll certainly get a trial by fire.

Right off the bat I noticed how smoothly the rudder turned when I turned the steering wheel, so that was a very good sign - they had properly aligned the entire bearing system, which was of course critical. Oliver warned me that I’d need to tighten the packing nut on the shaft seal, and tighten the new steering cabled after some hard sailing. We did notice the packing leaking on the way up - and it was a boisterous sail, blowing 25-30, and broad-reaching with just the big genoa, making 8-9 knots the whole way. I’ve since tightened that. Otherwise, the whole thing looks pretty bulletproof to me, but I suppose only time will tell.

Tomorrow we sail for Culebra for a brief respite before continuing on to Fajardo where the new crew arrives on Friday April 1. Then we’re Havana bound! Stay tuned!

Rudder Repair Photo Gallery - Click each for slideshow with captions.